Susū mai i a matou uepisaite!

Elemene fa'avevela FeCrAl ocr23al5 e tete'e maualuga mo le ogaumu

FeCrAl ocr23al5 fa'avevela tete'e maualugafasipepaelemene mo le ogaumu

| Vasega | 0Cr23Al5 |

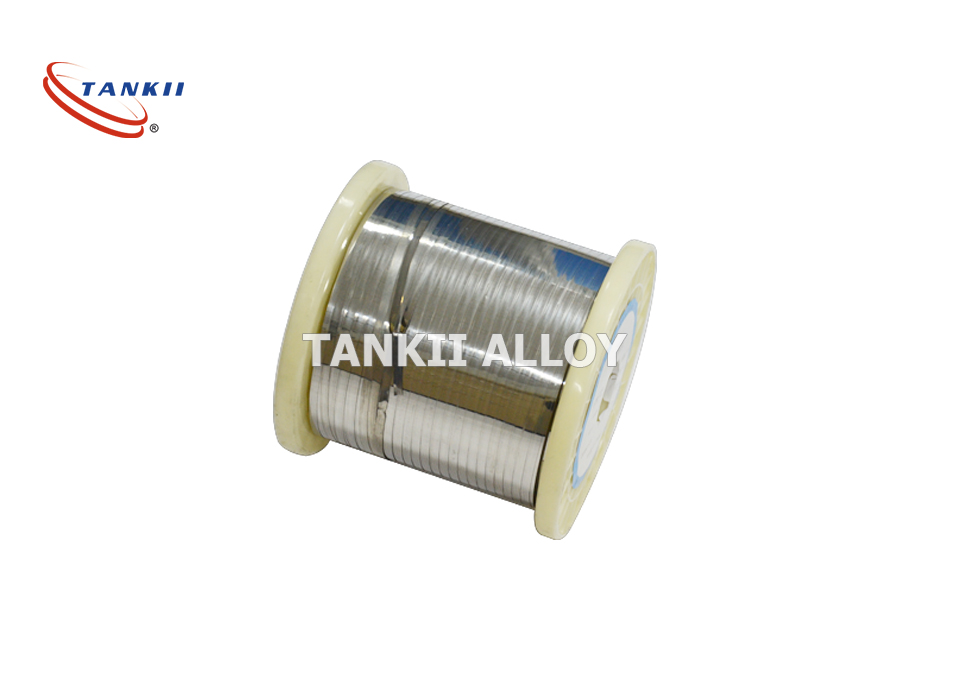

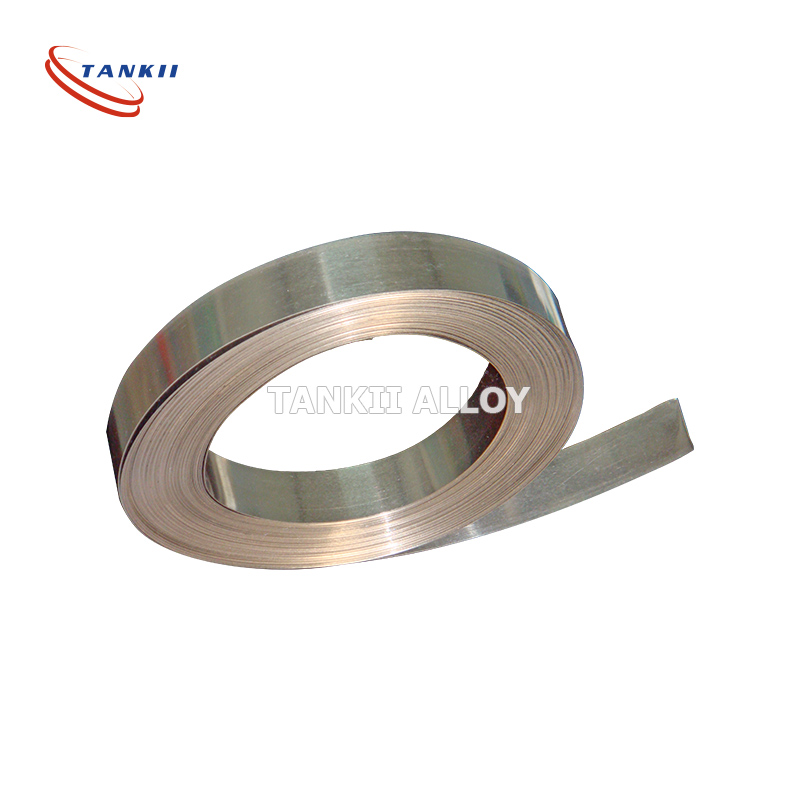

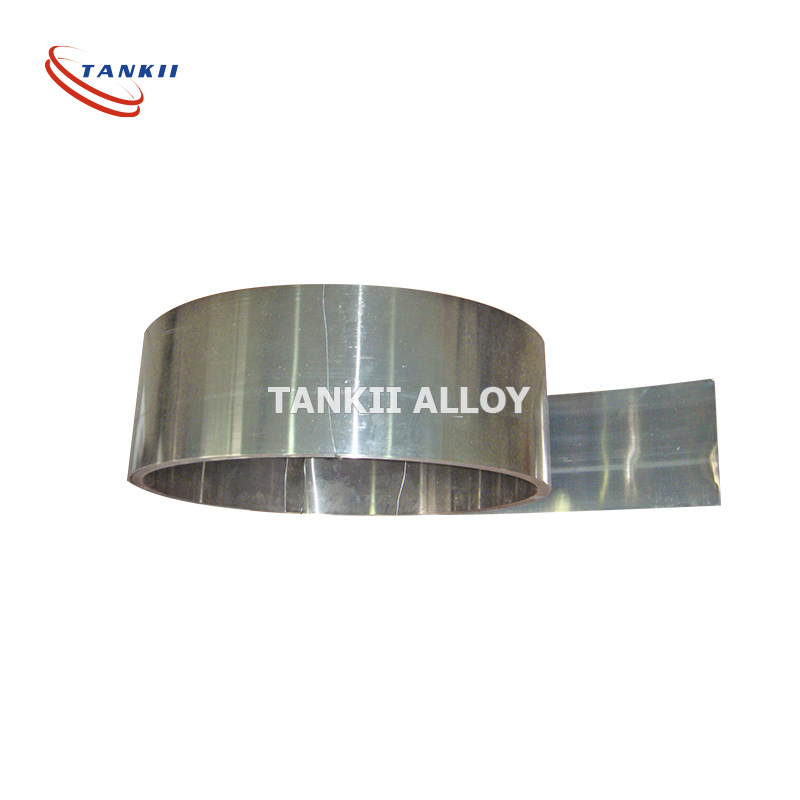

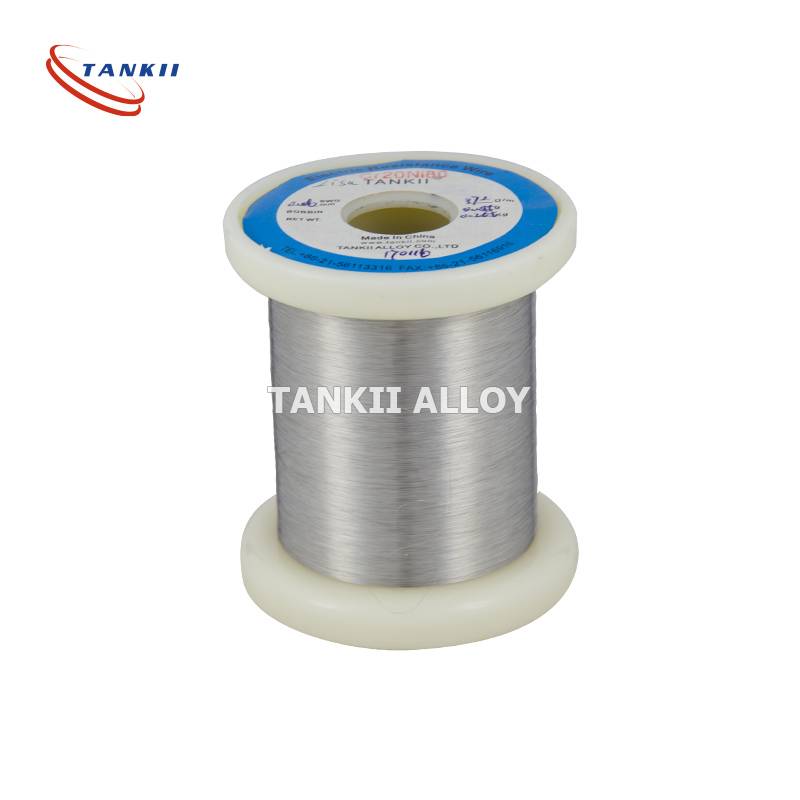

| Tele | mafiafia: 0.05-3mm lautele: 4-250mm |

| Luga | tipi pupula |

| Mamafa | 1-3kg/roll, e tusa ai ma le aofaʻi o tagata faʻatau |

| Tete'e | 1.3±0.05μΩ.m |

| Ma'a'a (HV) | 180-210HV |

| Fa'aloloa | ≥16% |

O le Shanghai Tankii ALloy Material Co.,Ltd. e taula'i i le gaosiga o le nichrome alloy, thermocouple wire, fecral alloy, precision alloy, copper nickel alloy, thermal spray alloy ma isi mea i foliga o uaea, pepa, lipine, fasipepa, u'amea ma ipu.

Ua uma ona matou maua le tusi faamaonia o le faiga lelei o le ISO 9001 ma le faamaoniga o le faiga puipuia o le siosiomaga ISO 14001. E ia i matou se seti atoa o gaosiga alualu i luma o le faamamaina, faaitiitia o le malulu, tosoina ma le togafitia o le vevela ma isi mea faapena. Matou te mitamita foi e iai lo matou gafatia tutoatasi i le R&D.

| Vasega | Vevela aupito maualuga | Tete'e | Faigata | Malosiaga o le tensile | Fa'aloloa |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Vasega | Fa'asologa o vaila'au% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | paleni |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | paleni |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | paleni |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | paleni | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | paleni |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | paleni |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | paleni |

Tusi lau savali iinei ma lafo mai ia i matou

Vaega o oloa

-

Telefoni

-

Imeli

-

Whatsapp

-

WeChat

Iutia

150 0000 2421

-

Pito i luga